a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

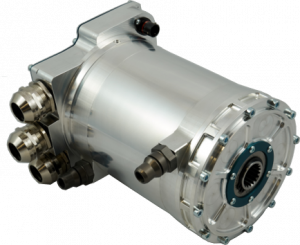

/// High Performance Motors

Revolutionary Winding Technology

SciMo has developed a groundbreaking and innovative winding technology that addresses the key challenges facing modern electric motors, including material efficiency, cooling performance, and cost. Our motor technology allows for electric motors with power densities of up to 17 kW/kg, making it a game-changer in the industry.

- 60% higher copper density

- 90% higher cooling performace

- 75% higher power density

- 75% higher material efficiency

/// Electric High Performance Motors

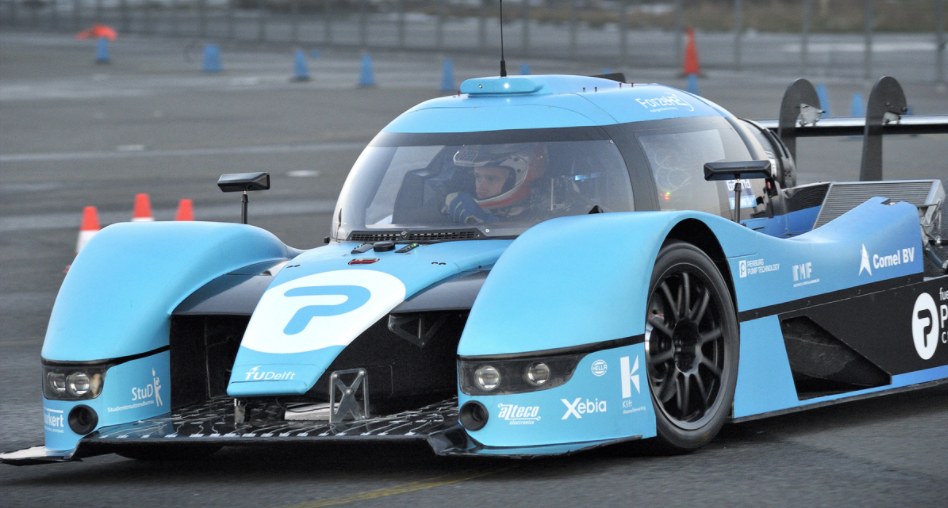

SciMo is producing electric motors with highest power to weight ratios. Our motors proved their potential in the most challenging aerospace and motorsport applications, leading to a world champion title in the forumla student in 2015. Our motor technology is ideal for applications that demand highest power density and efficiency, such as high-efficiency motors, special motors and test bench motors. A comprehensive overview of our motor specifications can be found in the table below.

Production motors

Motors | Type | Pole pairs | Speed (rpm) | eta (%) | Max. power (kW) | Cont. power (kW) | Cont. Torque (Nm) | Weight or inertia | Application |

|---|---|---|---|---|---|---|---|---|---|

SY23.C | Inrunner | 2 | 25,000 | 95 | 40 | 20 | 15 | 0.5 gm² | Dynamic Dyno |

SY33.A | Inrunner | 3 | 40,000 | 95 | 150 | 70 | 43 | 11.7 kg | Motorsport |

SY33.B | Inrunner | 3 | 15,000 | 95 | 100 | 30 | 30 | 2 gm² | Dynamic Dyno |

SY43.B | Inrunner | 4 | 30,000 | 97 | >180 | 100 | 80 | 13.0 kg | Motorsport |

SY45.B | Inrunner | 4 | 30,000 | 96 | 300 | 200 | 120 | 6 gm² | Testbench Dynometer |

SY46.A | Inrunner | 4 | 30,000 | 97 | 500 | 200 | 120 | 16 gm² | Testbench Dynometer |

SY46.B | Inrunner | 4 | 20,000 | 97 | 400 | 200 | 150 | 16 gm² | Testbench Dynometer |

We cannot show all the customer specific motors here.If you have an interesting project with challenging motor requirements, please contact us!

Production motors (not for new design iteration)

Case studies

Motors | Type | Pole pairs | Speed (rpm) | eta (%) | Max. power (kW) | Cont. power (kW) | Cont. Torque (Nm) | Weight (kg) | Application |

|---|---|---|---|---|---|---|---|---|---|

SY2X.A | Inrunner | 2 | 70,000 | >96 | >100 | >100 | 17 | – | Generator (stackable up to 300 kW) |

SY61.B | Inrunner | 6 | 6,000 | 97

| 100 | 400 | 200 (600 max.) | 35 | Testbench Dynometer |

SY61.X | Inrunner | 6 | 10,000 | 98 | 250 | 250 | 280 | 100 | Ultra high efficiency |

SY4X.A | Inrunner | 4 | 18,000 | 98.4 | >400 | 250 | 300 | 30 | Formula E (efficiency optimized) |

SCFX.A | Outrunner | 15 | 3,000

| >90

| 16 | 12 | 38 | 4.2 | Aerospace |

SYKX.A | Inrunner | 20 | 3,000 | 97 | 1700 | 1200 | 6000 | <200 | Aerospace 1.5 MW direct drive |

/// Motor technology

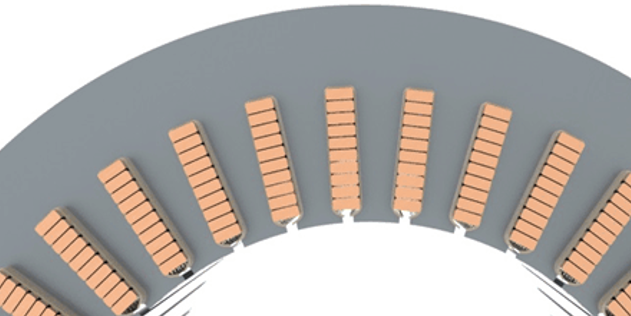

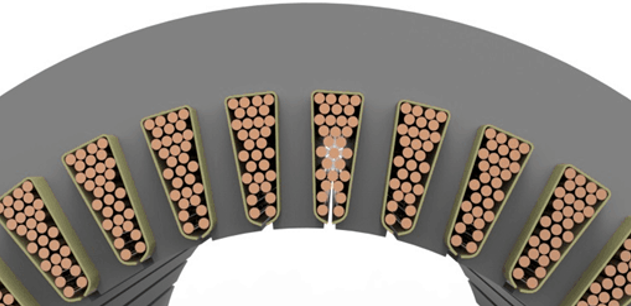

/// Winding Technology

SciMo has completely redesigned the optimal winding for electric motors, utilizing thin rectangular flat wires that significantly increase the copper density within the motor. Our innovative winding technique enables the use of distributed windings with copper filling factors above 70%, resulting in improved power density and efficiency. Additionally, the material savings in magnets and electric sheet lamination can offset the increased manufacturing costs of the winding process. Overall, our approach to coil winding has the potential to revolutionize the way electric motors are designed and manufactured.

/// Conventional Winding

Distributed winding using round wires:

- around 45% copper filling factor

- bad heat dissipation

- manual phase connection

/// Motor Design and Optimization

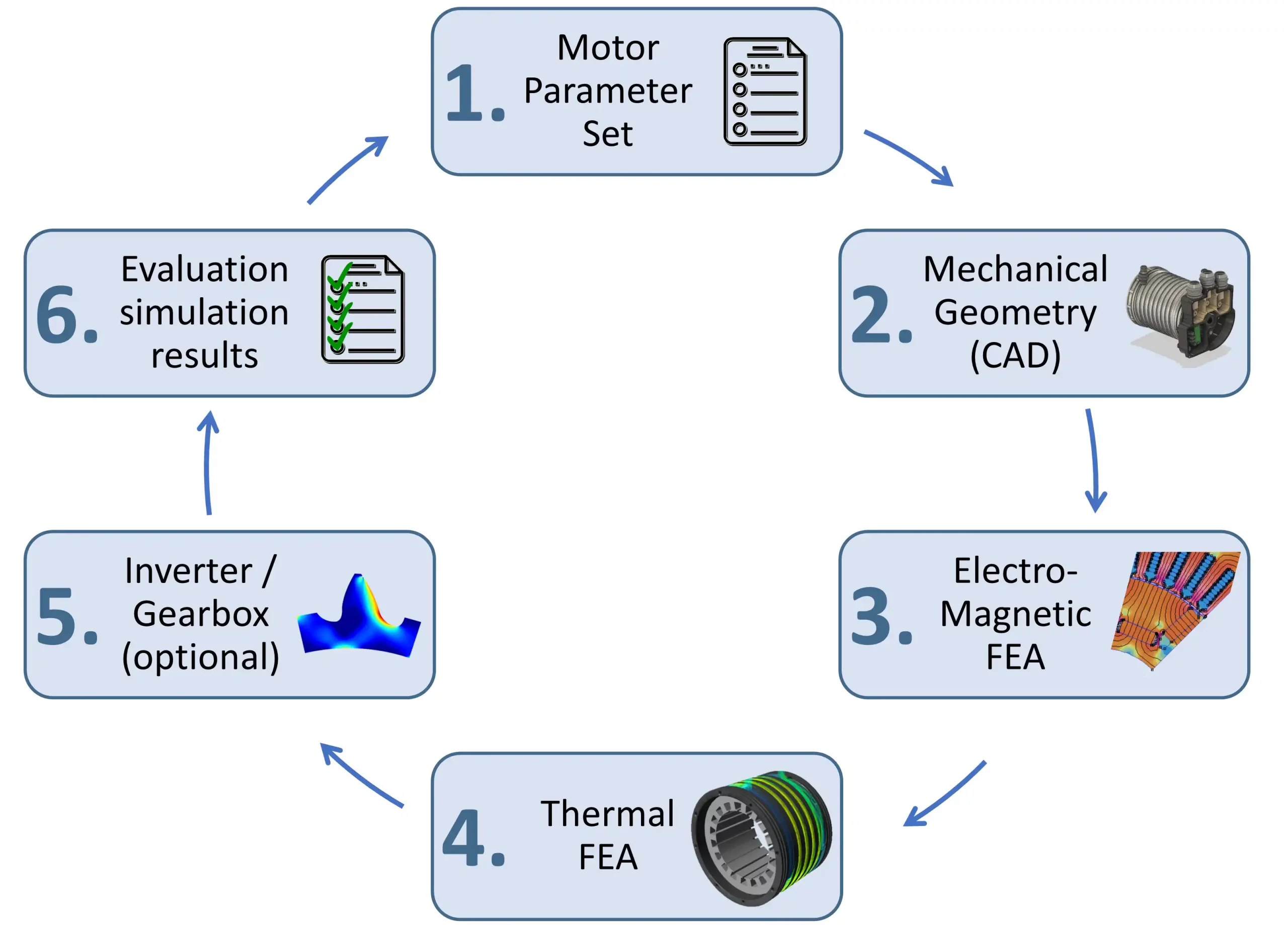

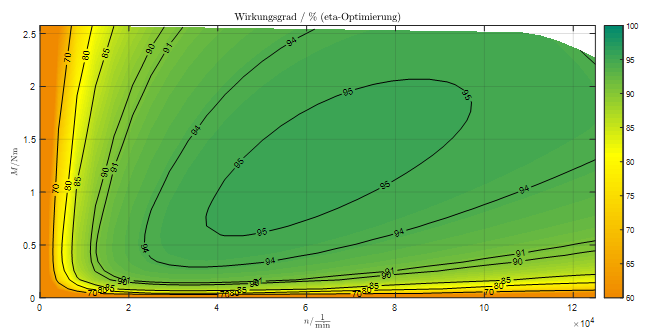

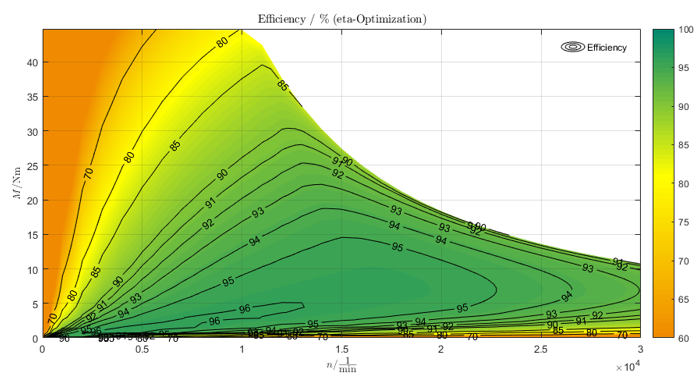

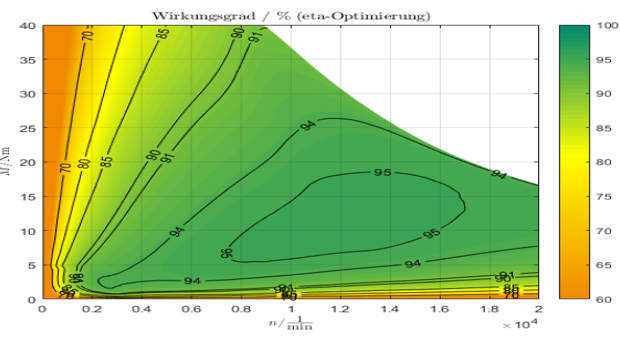

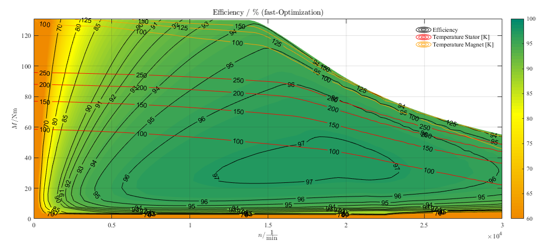

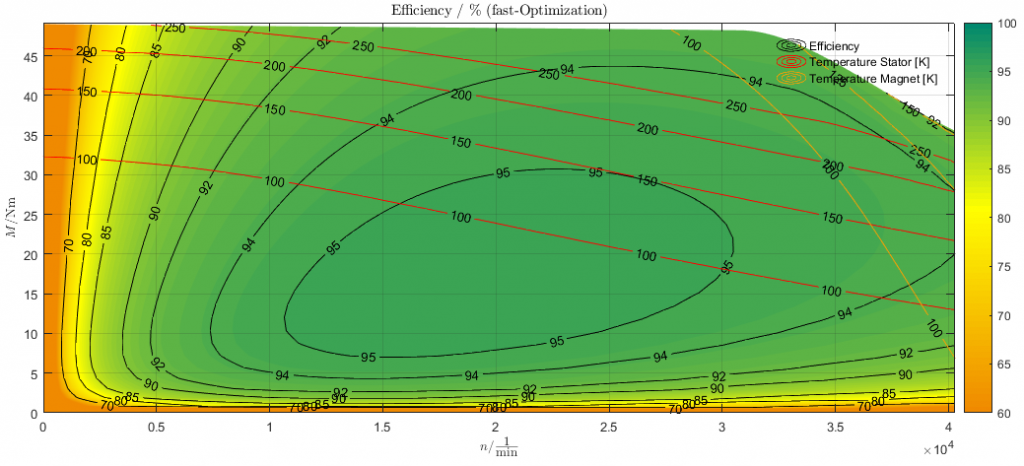

At SciMo, we have developed a fully automated, closed-loop process for designing and optimizing the electromagnetic layout of our motors. This process involves detailed simulation of the electric drive system, which allows us to create motors that operate at the highest levels of performance while approaching physical limits.

Our approach involves an iterative process in which we use a fully automated simulation toolchain to achieve a global maximum. We also cross-check the results against test bench measurements in order to refine the simulation process. This continuous improvement of our simulation toolchain enables us to optimize the electromagnetic design of our motors.

- Unique parameter set describes the geometry and materials.

- The geometry is generated in high detail.

- Fully parallelized electromagnetic FEA is performed.

- Generation of a full 3D thermal FEA. Results are simplified to a thermal network of components of interest.

- Output motor data can be used to directly optimized inverter and gearbox design for particular machine layout.

- The simulation results are evaluated and used as feedback for an optimization of the parameter set to start with the next iteration.

The simulation results or output modell fully characterizes the entire drive system, which can be used to apply loadcycles and calculate the expected thermal response. As well, more complex simulations can be performed, for example calculation the maximum dynamics.

The tool chain is regulary benchmarked against test bench runs with our different motors. Deviations between simulations and measurement results are used as input data to optimized the simulation model.

/// Applications

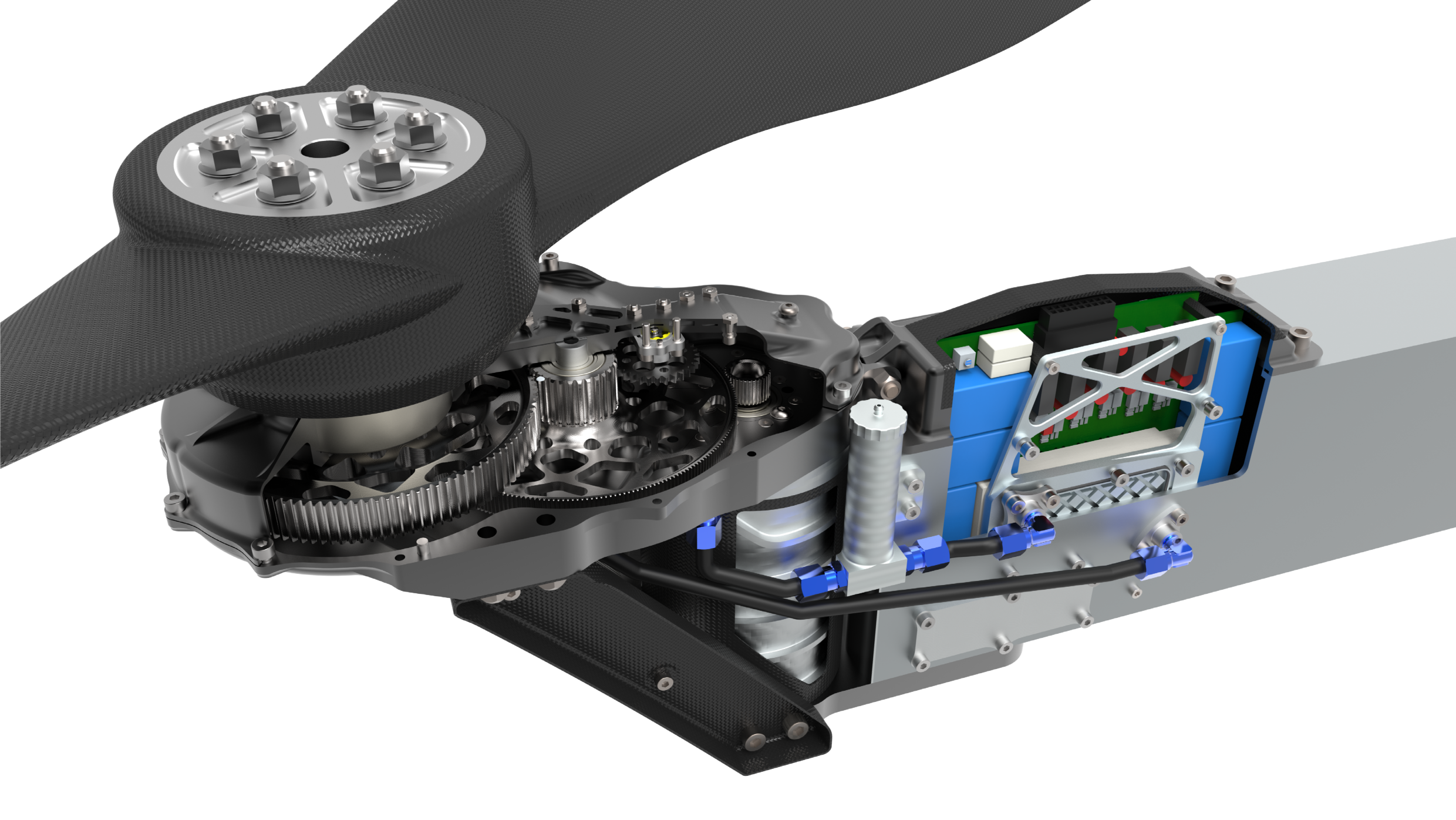

SciMo motors are used in a wide range of applications. Our technology leads to light, efficient and powerful motor designs with highest power densities. The motors are therefore used in a wide range of applications, e.g. Traction motors, e-Booster, electric turbocharger, test bench motors, spindel drives, fly wheels, pumps, compressors.

/// Motor specifications

/// SY11

Motor parameters of the SY11 high speed motor.

Design parameter | Value |

|---|---|

Pole pairs | 1 |

Airgap diameter (mm) | 20 |

Active length (mm) | 50 |

Winding | distributed |

Magnet config. | buried |

Cooling | Water jacket |

Status | Prototype |

Property | Value |

|---|---|

Maximum speed (rpm) | 125.000 |

Maximum efficiency (%) | >94 |

Maximum power (kW) | 25 |

Continuous power (kW) | 5 |

Continuous torque (Nm) | 0.4 |

Weight (kg) | 2.0 |

/// SY21

Motor parameters of the SY21 motor with highest power density.

Design parameter | Value |

|---|---|

Pole pairs | 2 |

Airgap diameter (mm) | 40 |

Active length (mm) | 80 |

Winding | distributed |

Magnet config. | buried |

Cooling | Oil cooling |

Status | Running in application |

Property | Value |

|---|---|

Maximum speed (rpm) | 30.000 |

Maximum efficiency (%) | 96 |

Maximum power (kW) | 50 |

Continuous power (kW) | 32 |

Continuous torque (Nm) | 18 |

Weight (kg) | 4.0 |

/// SY31

Motor parameters of the SY31 motor with high power density.

Design parameter | Value |

|---|---|

Pole pairs | 3 |

Airgap diameter (mm) | 60 |

Active length (mm) | 66 |

Winding | distributed |

Magnet config. | buried |

Cooling | Water jacket |

Status | Running in application |

Property | Value |

|---|---|

Maximum speed (rpm) | 20.000 |

Maximum efficiency (%) | 95 |

Maximum power (kW) | 70 |

Continuous power (kW) | 30 |

Continuous torque (Nm) | 25 |

Weight (kg) | 5.3 |

/// SY43

Motor parameters of the SY43 motor with highest performance.

Design parameter | Value |

|---|---|

Pole pairs | 4 |

Airgap diameter (mm) | 80 |

Active length (mm) | 100 |

Winding | distributed |

Magnet config. | buried |

Cooling | Water jacket |

Status | In Production |

Property | Value |

|---|---|

Maximum speed (rpm) | 30.000 |

Maximum efficiency (%) | 97 |

Maximum power (kW) | 180 |

Continuous power (kW) | 100 |

Continuous torque (Nm) | 80 |

Weight (kg) | 13.0 |

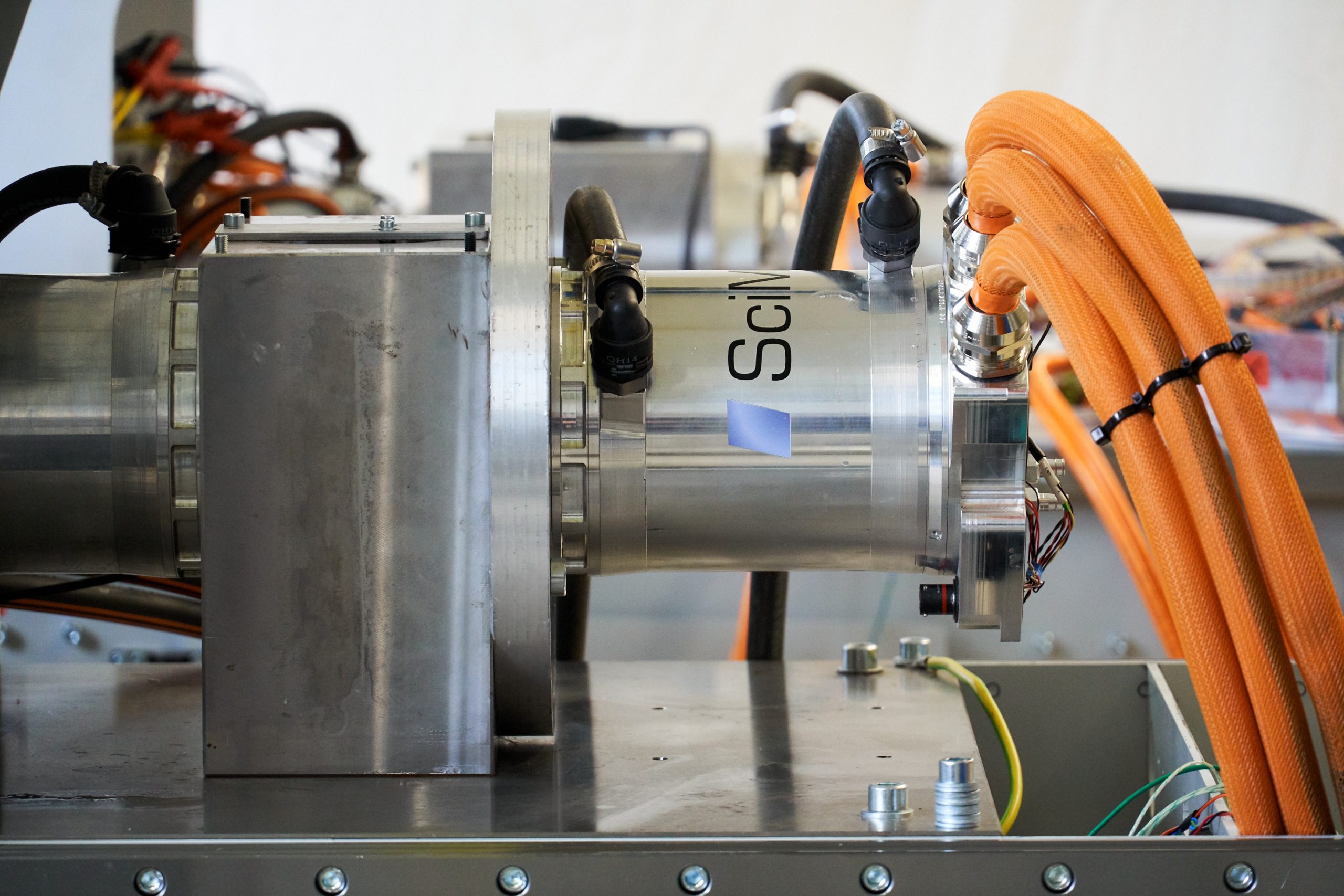

/// SY3X.A Testbench dynometer

Due to its high power density SciMo motors are ideally suited for high speed, high power dynometers with very high dynamics. There are not many motor suppliers that can generate such high continuous output powers from such small rotor dimensions. And small rotor dimensions help to deal with critical bending frequencies.

Design parameter | Value |

|---|---|

Pole pairs | 3 |

Airgap diameter (mm) | 60 |

Active length (mm) | 100 |

Winding | distributed |

Magnet config. | buried |

Cooling | Water jacket |

Status | Running in application |

Property | Value |

|---|---|

Maximum speed (rpm) | 40.000 |

Maximum efficiency (%) | 95 |

Maximum power (kW) | 150 |

Continuous power (kW) | 100 |

Continuous torque (Nm) | 43 |

Weight (kg) | – |