a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

/// Consulting

SciMo has a deep knowledge in developing and designing electric motors at the physical limit. We offer expert consulting services for the following topics:

- Electromagnetic Design of PMSM

- Controller Technology

- Modelling and Identification of Electric Drive Systems

- Concept validations and concept designs

- Mechanical Design

- High speed drives and bearings

- Sourcing of motor and inverter specific components (e.g. iron laminations and magnets)

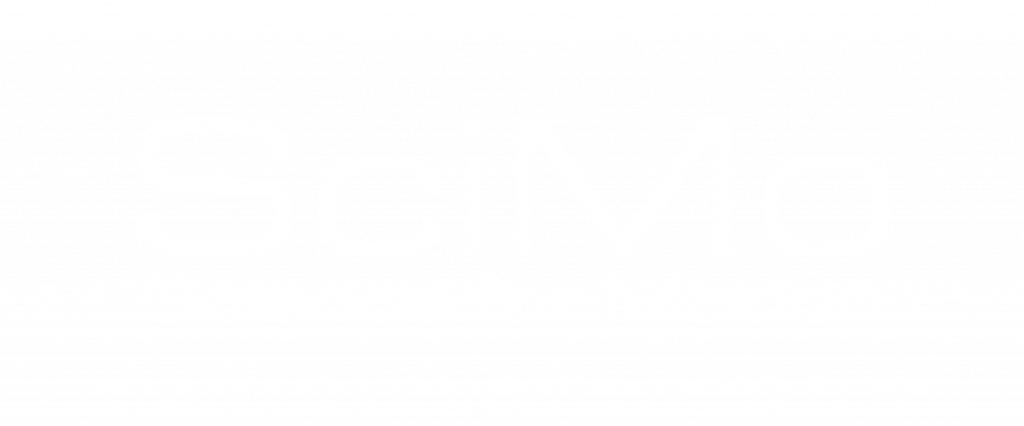

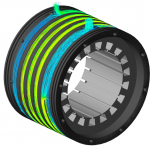

/// Electromagnetic Design

SciMo has a deep knowledge of the electromagnetic (EM) design process of electric motors. We offer our expertise to improve your motor with detailed electromagetic FEM simulation of the entire electric drive system.

/// Controller Technology

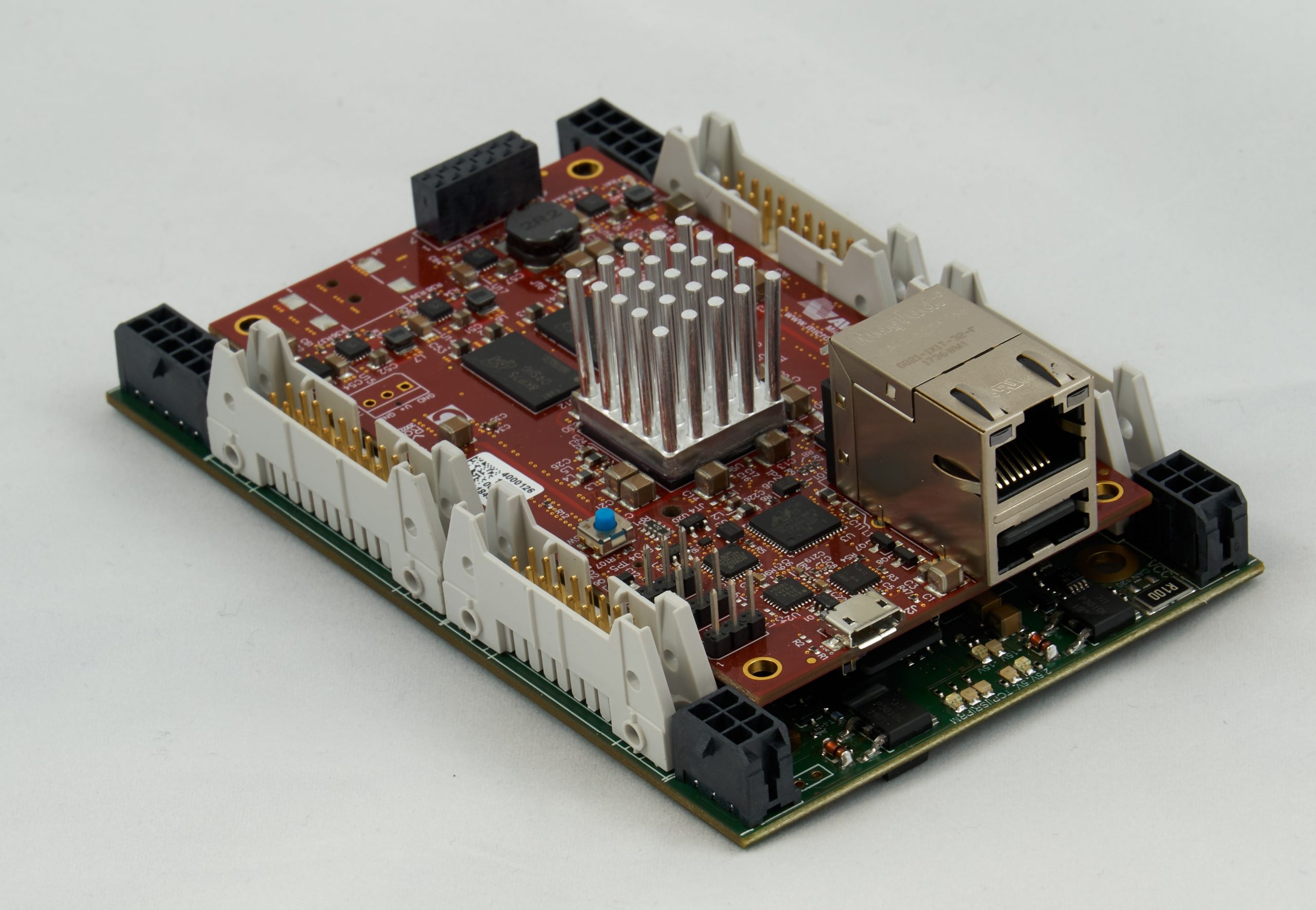

SciMo developed advanced control algorythm for inverters to power electric drive systems. Depending on the application, we rely on a reasonable combination of modern and conventional control algorithms.

- Short development times

- Direct implementation of algorithms on custom rapid prototyping platform

- Testing of controller performance on test benches

- Real-time monitoring software for online or offline controller parameterization

/// Modeling and Identification

The modelling of electric drive systems is one of our central competences. Physical models are used to describe the system mathematically. Identification algorithms are used to determine the model parameters with the help of real measurement data from the test bench.

A new, very detailed non-linear modelling approach also considers effects such as:

- Iron losses

- Copper losses

- Friction and turbulence losses

- Saturation

- Inverter losses

The dependence of the stator and rotor temperature is also modeled.

The models are used for the simulation of the motor behaviour as well as for the model-based controller design. The exact consideration of the non-linear effects can significantly increase the controller performance compared to the state of the art.

/// Simulation

Due to many years of experience and knowledge in the field of modeling of electric drive systems, we have very detailed simulation models for:

- Tests during controller design

- Analysis and test of the entire drive system

- System optimization

In this way, the behavior of the engine can be analyzed in detail even before a prototype is manufactured. The parameterization of the simulation and design models is carried out from the data of the FEM simulations of the machine. Thus, the control system for the measurement of the machine can be parameterized on the test bench before the measurement of the real machine.

In addition, after the machine measurement the model can be parameterized with the data from the measurement and thus further improved. Simulation with these models has the following advantages compared to testing on the test bench:

- Simulations at limits without danger are possible

- Cost savings compared to operation on the test bench

- Test of algorithms for control and regulation without danger in case of instability

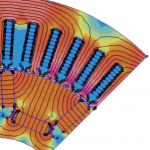

/// Mechanical Design

Some of the key areas we are working on are:

- High speed drives and bearings

- Strength calculation

- CFD-Simulation vof cooling fluid flows

- Manufacturable design

- Drawings

/// Automation & Process Technology

SciMo is expert in automation technology and developed its on automation hardware to design and build highly automated manufactring processes. Our automation hardware relies on open source soft- and hardware for an easy and quick usability.