a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

/// CNC machining in Karlsruhe

Manufacturing of special parts

SciMo is a trusted and reliable manufacturer of high-performance motors based in Karlsruhe. With our own production capabilities and expertise in producing milled and turned parts, we are able to deliver special mechanical engineering components with precision, quality, and speed. Our customers recognize us as a quality-focused partner.

- Special parts according to customer specifications

- Precision and care

- Turning, Milling & Assembly

- From quantity: 1

- Fast, Flexible & Individual

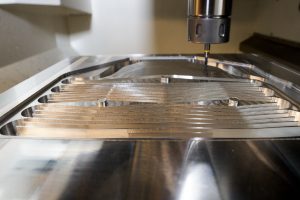

/// CNC Milling & Turning

/// CNC Manufacturing

Our production center is equipped with the latest technologies for metalworking, including CNC machines controlled by advanced CAM processors.

If you have a drawing or 3D CAD model, we can provide a quick quote for your project. With years of experience in producing our own powertrain components, we have expertise in the production of thin-walled housing parts, hollow shafts, and transmission components. We can also precisely machine solid steel parts for use in test and assembly applications. If you need fast and reliable production of your parts, we are the perfect manufacturing partner for you.

/// Quality

At SciMo, we understand the importance of delivering the highest quality, reliable, and functional products to our customers. Our dedicated employees are integral in achieving these standards, using their commitment and innovative skills to drive the success of our company.

We follow a strict quality management system based on ISO 9001, which was certified in 2019. In addition, our partnerships with customers and partners in the automotive industry help us to continually improve our quality management to ensure consistently reliable manufacturing processes that produce top-quality products.

/// Machining Technology

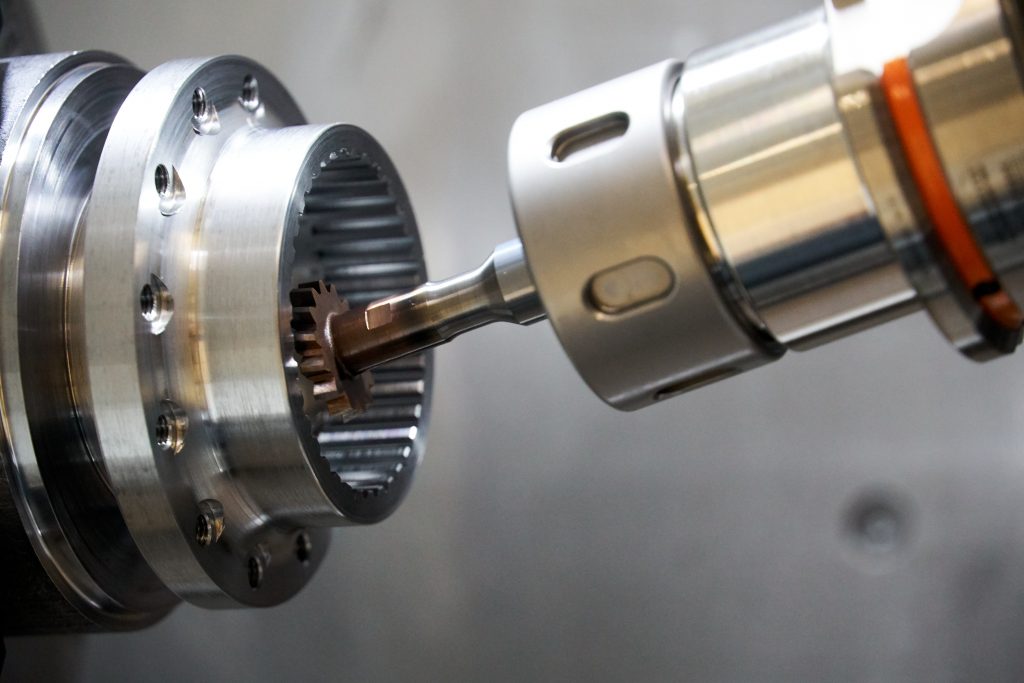

/// Gear cutting technology

For gear cutting, we work with the peeling or broaching process.

With the help of our self-developed process and the associated software for generating the machine code, we can produce almost any gear geometry. Deviations from standard or standardized gearings are no problem for us.

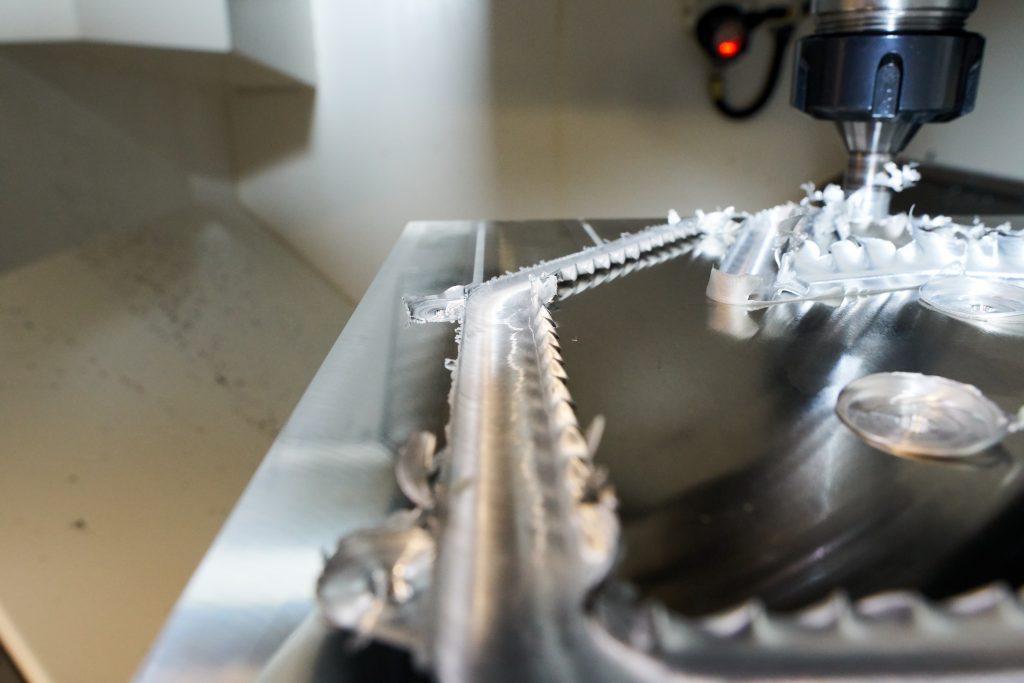

/// Friction stir welding

In friction stir welding, two components are joined without the addition of material. The subsequent milling over of the weld seam means that none of this is visible.

We have established the friction stir welding process in our company for the integration of cooling channels in housing parts. The process provides an easy, safe and good-looking way to close cavities in milled parts.

Many other applications of this process are conceivable. Contact us to learn more about the possibilities of this innovative process.

/// Skiving

The gear skiving technology is a modern machining technique for the production of inner and outer gears and is an alternative to broaching and slotting. Skiving is an established process at SciMo and offers the highest quality combined with high manufacturing flexibility.

/// Thin wall aluminum parts

Light, thin and yet strong aluminum parts are our daily business.

We always have a selection of aluminum raw material of different alloys in stock to respond quickly to your request.

/// Machinery

Below you will find a selection of our popular machine models.

/// DMG Mori CMX 600 V

3-axis vertical milling center

Eigenschaften | Wert |

|---|---|

Max. x Weg (mm) | 600 |

Max. y Weg (mm) | 560 |

Max. z Weg (mm) | 510 |

Max. Tischgewicht (kg) | 600 |

Tischlänge (mm) | 900 |

Tischbreite (mm) | 560 |

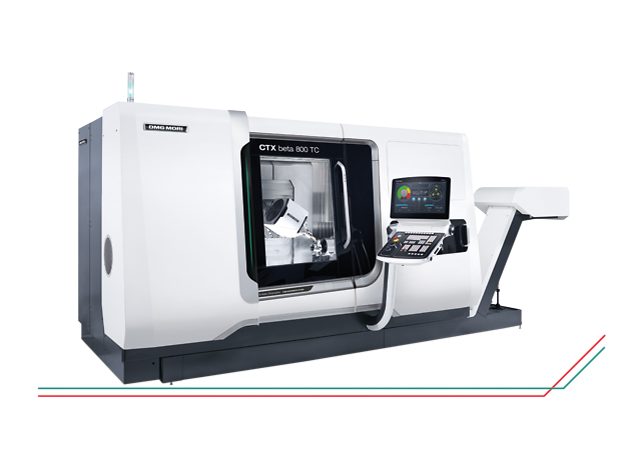

/// DMG Mori CTX Beta 800 TC

5-axis turning-milling machining center

Eigenschaften | Wert |

|---|---|

Max. Drehdurchmesser (mm) | 500 |

Max. Drehlänge (mm) | 800 |

Integrierter Spindelmotor mit C-Achse (0.0001°) | 5000 |

Max. Spannrohr Innendurchmesser (mm) | 102 |