a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

/// Power Electronics and Inverter

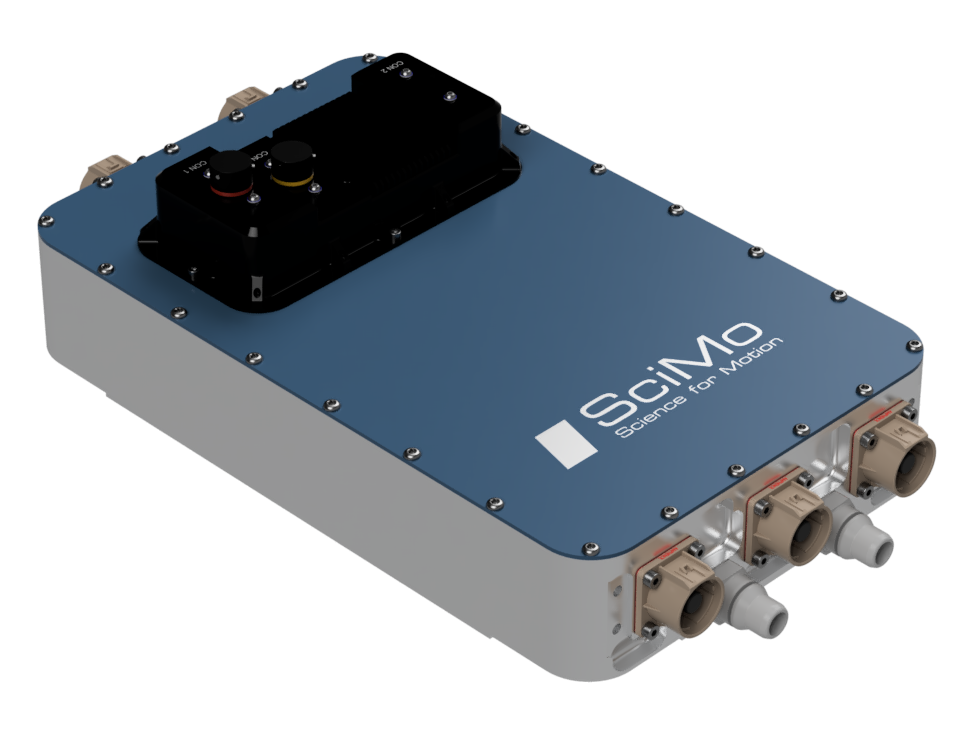

SciMo’s inverter technology is based on years of experience and optimization. Application-oriented development in the field of electric motors has resulted in a both powerful and reliable platform. The inverters are optimized for operation with SciMo-motors, but can also be adapted to drive any motor system.

/// Inverters

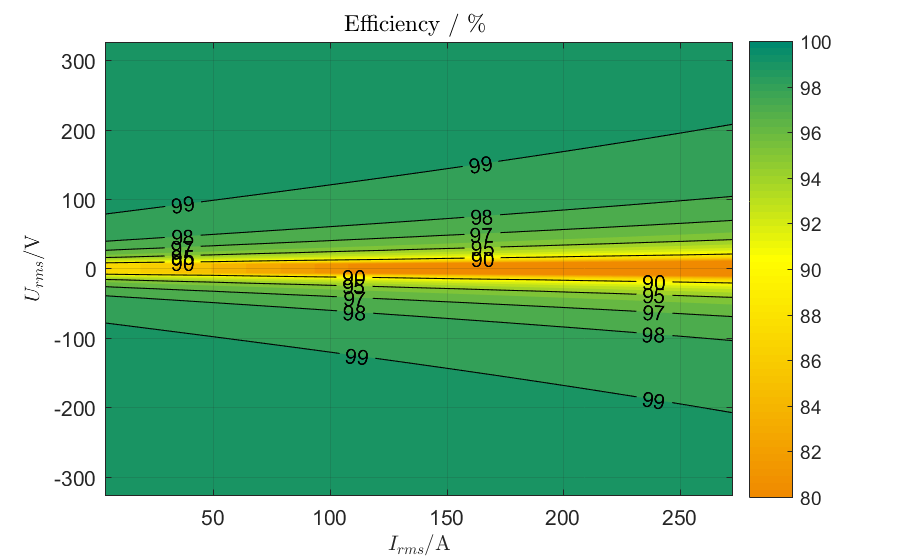

SciMo is producing power electronic hardware based on SiC-MOSFET- and Si-IGBT-modules. All our inverters are optimized for highest power density and a DC voltage of 800V to 900V.

Complementing our portfolio, we develop custom inverters fast and efficiently. Due to our in-house prototype manufacturing and slim design processes and we are also able to offer a competitive, great value.

Custom design meeting your demands are available through our engineering services.

/// Applications

SciMo has a deep knowledge in power electronics to enable the full performance of our advanced motor technology. This contains advanced controller technology using a non-linear predictive control algorithm for highly dynamic torque control, highly dynamic speed control as well as sensor fault-detection during runtime. Our inverters are used in a variety of applications. A short overview can be found in the motor section.

If you are looking for an inverter for other applications just contact us.

/// Inverter Technology

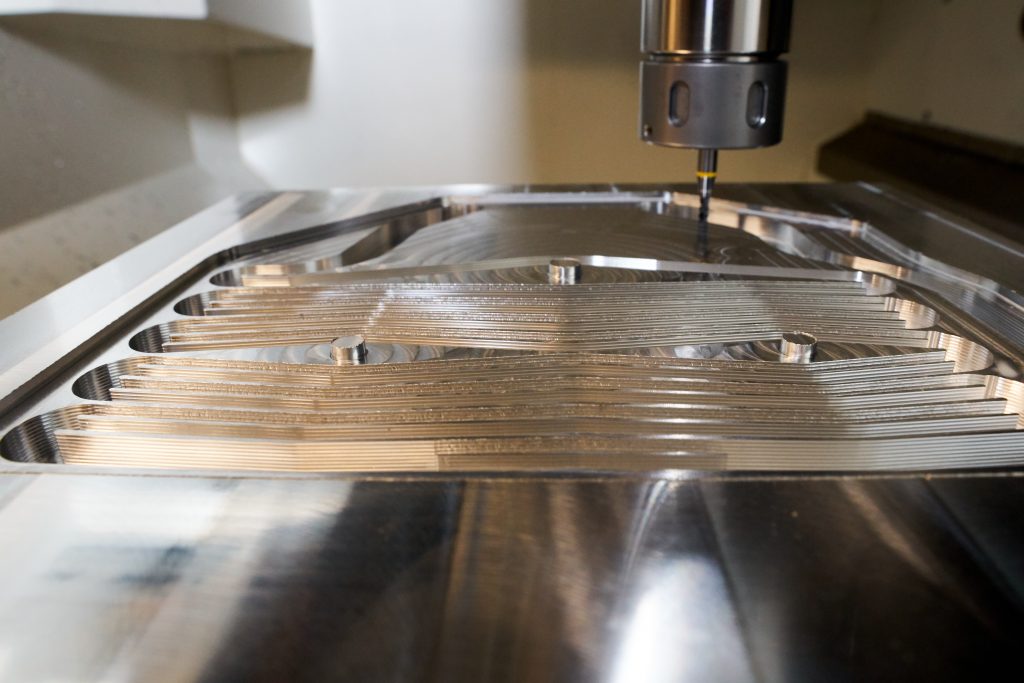

SciMo uses advanced manufacturing technologies in its own production center to give the inverter systems the best characteristics in terms of power density and functionality.

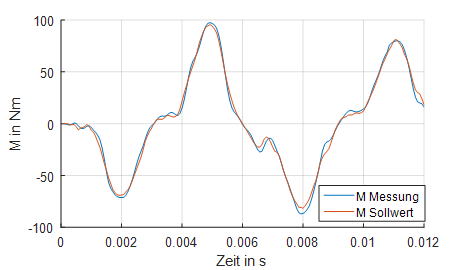

/// Control Technology

We are experts in the field of control of electric drive systems. Depending on the application, we rely on a reasonable combination of modern and conventional control algorithms.

When developing new concepts or customizing the control system, we achieve short development times by directly implementing the algorithms on our own rapid prototyping platform. New algorithms are tested directly on our engine test benches. With the help of our real-time monitoring software, we can parameterize the controllers directly on the test bench or subsequently optimize them offline using the measurement data from the test bench.

We use modern control algorithms such as:

- Non-linear predictive control

- Optimal control

- Load torque observer

- Robust sensorless control

- Efficiency-optimized control

- Highly dynamic torque control

- Highly dynamic speed control

- Sensor fault-detection during operation

- Sensorless control during fault-condition

Due to many years of experience in the fields of control engineering and drive systems we are the perfect partner for developing or improving your drive control system.

/// Lightweight construction

The aluminum lightweight housings of the inverter systems achieve the necessary robustness and a protection class of IP67 with minimum weight due to their optimized design.

/// Innovative cooling concepts

Just as with the motors, the performance of the inverter system can be increased by improving the cooling of the power semiconductors. For this reason, SciMo focuses on innovative cooling concepts such as the manufacturing of high-performance cooling channel systems by the friction stir welding process or the direct water cooling of module cold plates. The sophisticated machining of the cooling plates and the complex fluid control systems are manufactured in-house.

/// Overview of power electronics

The following list shows some examples of inverters developed by us with performance specifications. We do not display customer-specific developed inverters.

All inverters feature a cooling loop which is directly integrated into the housing, resulting in an optimal thermal transition coefficient between coolant and modules. A water/glycol mixture is used as coolant.

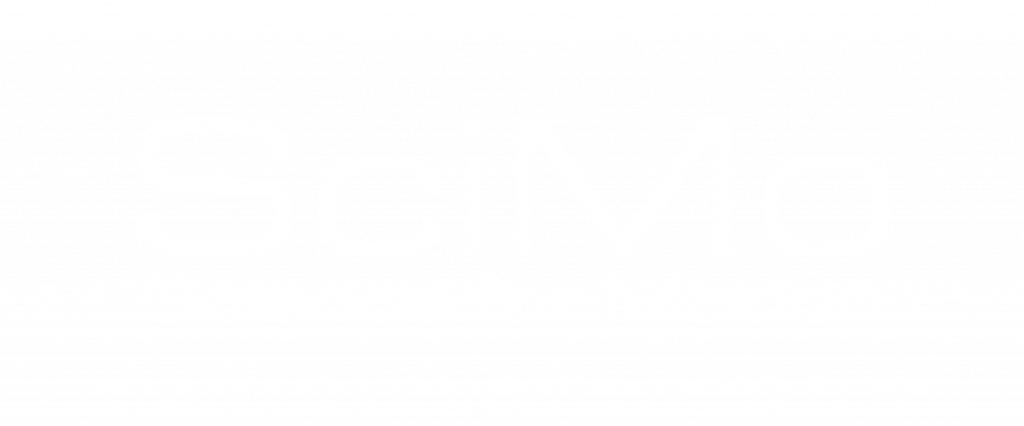

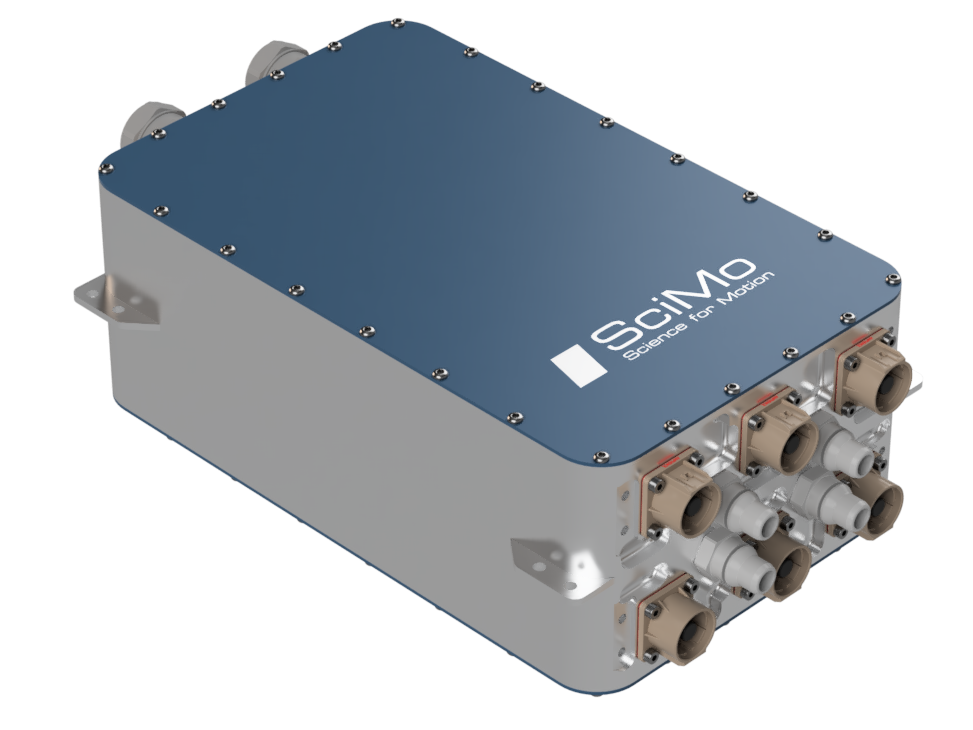

/// ISC2 - platform

The ISC2 is a high power SiC inverter enabling the most demanding applications where high speed machines are driven with high currents.

Inverter | DC link (V) | Continuous Current (A) | Weight (kg) | Switching Frequency (kHz) |

|---|---|---|---|---|

ISC2-A1-12X-400EPC-800-1C-C | 800 | 350 | 6.5 | 20 – 60 |

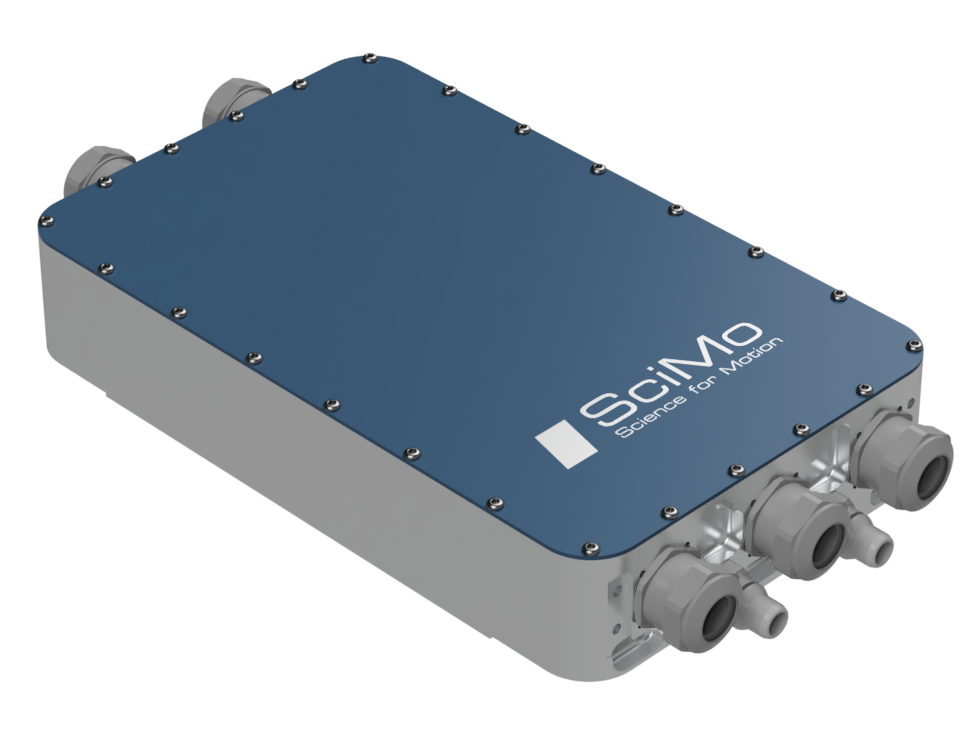

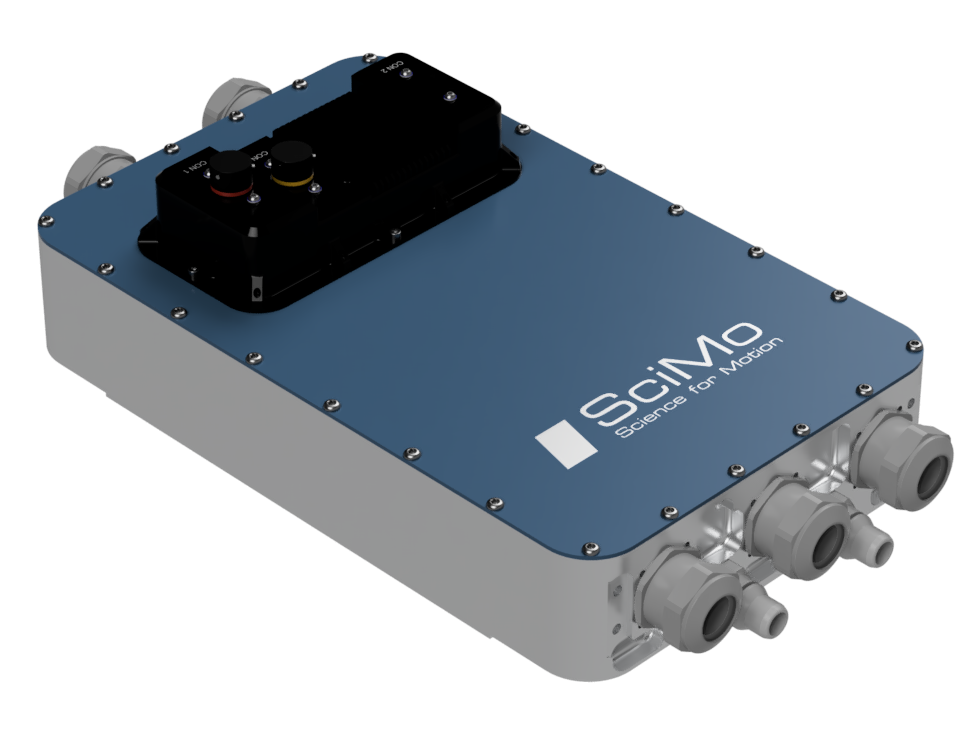

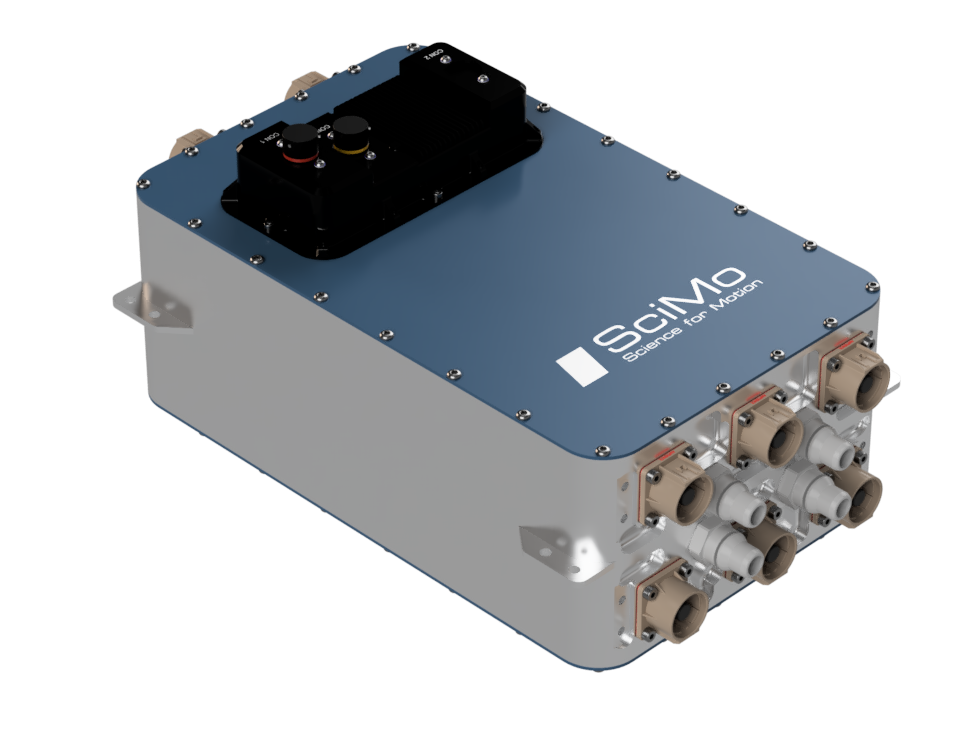

/// ISI2 - platform

The ISI2 Si-IGBT inverter is a high power-density water cooled inverter for synchronous motors/generators. Combined with the Xilinx Zync based SciMo controller it offers the latest model-base control technology to allow superior control of highly utilized, highly saturated, high speed machines.

A special feature of the ISI2 powerstage platform is the possibility to connect multiple powerstages to one controller. Up to two motors can be powered with two single powerstages each, offering up to 800 ARMS peak current per (6-phase) motor. Or one (12-phase) motor can powered with up to 1600 ARMS with 4 powerstages. Test

Inverter | DC link (V) | Continuous Current (A) | Weight (kg) | Switching Frequency (kHz) |

|---|---|---|---|---|

ISI2-B1-12X-400X-800-X-X | 800 | 320 | 7.0 | 14 |

ISI2-B1-12X-400X-900-X-X | 900 | 320 | 7.0 | 14 |

ISI2-B1-12X-800X-800-X-X | 800 | 640 | 7.0 | 14 |

ISI2-B1-12X-800X-900-X-X | 900 | 640 | 7.0 | 14 |

Controller | Type | AD Converter | Housing |

|---|---|---|---|

IMC5-C-D-16-MSH | Dual MOT | 16 bit | Motorsport Housing |

IMC5-C-D-16-MSHT | Dual MOT | 16 bit | Motorsport Housing TOP |

Example configurations of the ISI2 platform:

ISI2-B1-12S-800EPC-800-1P-P

ISI2 Double Stage

ISI2-B1-12S-800IPC-800-1P-P

ISI2 Double Stage with integrated Controller

IMC5-C-D-16-MSH

Package of an external motor controller

*The inverters shown are only an excerpt from the ISI2 platform. Please contact SciMo for more detailed information.