Contact:

Dr.-Ing. Markus Schiefer

E-Mail: info@sci-mo.de

Phone: +49 (0) 152/34271190

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

/// Innovative Technologies for Electric Motors

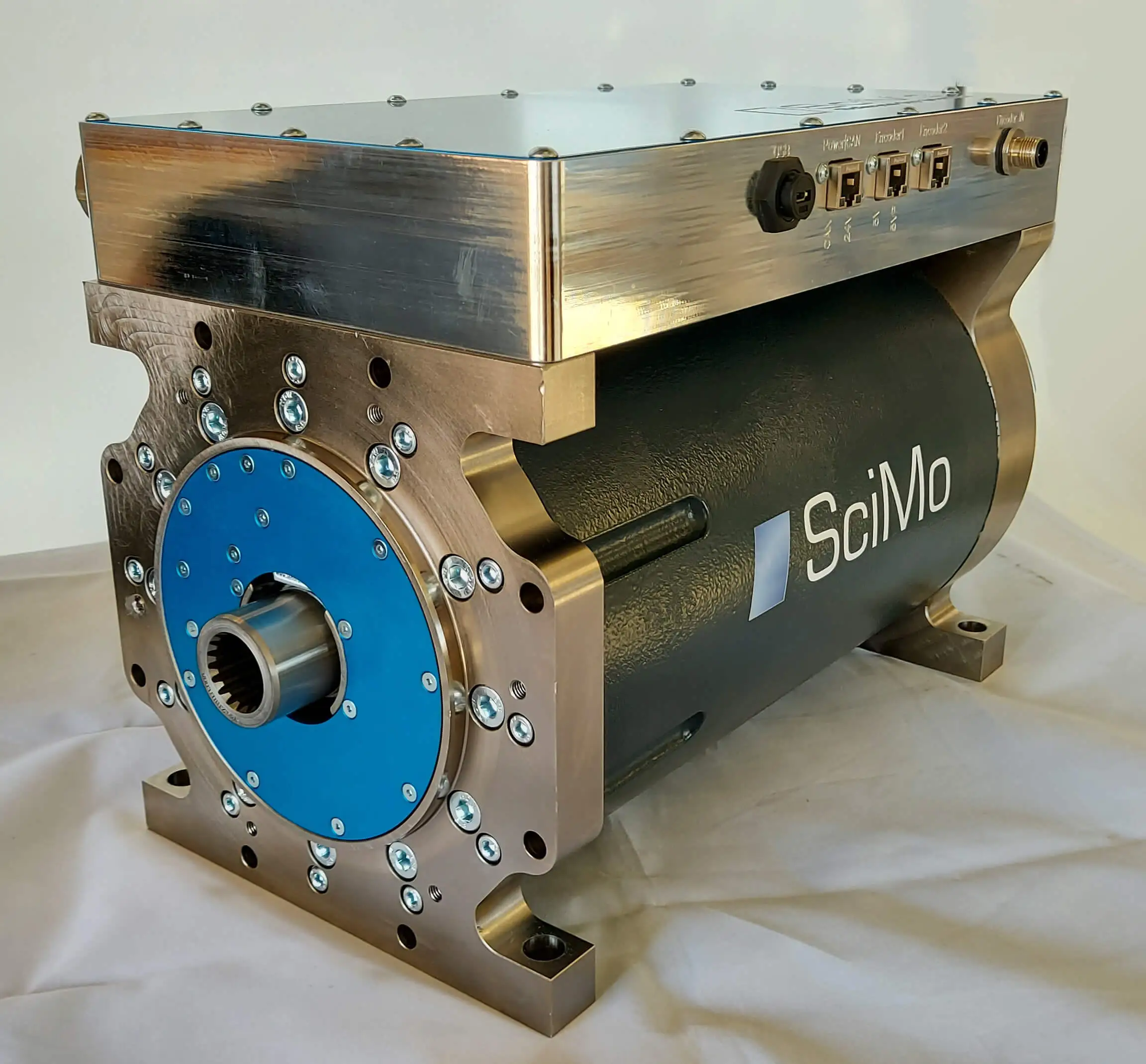

SciMo electric motors have been developed and utilized since 2013, boasting peak power densities of over 17 kW/kg and continuous power densities above 10 kW/kg. This advanced motor technology is suitable for applications that demand the highest levels of power density and efficiency, such as high-efficiency motors, specialized motors, and test bench motors. Our motors have already been proven in various racing series and have consistently demonstrated the highest quality standards.

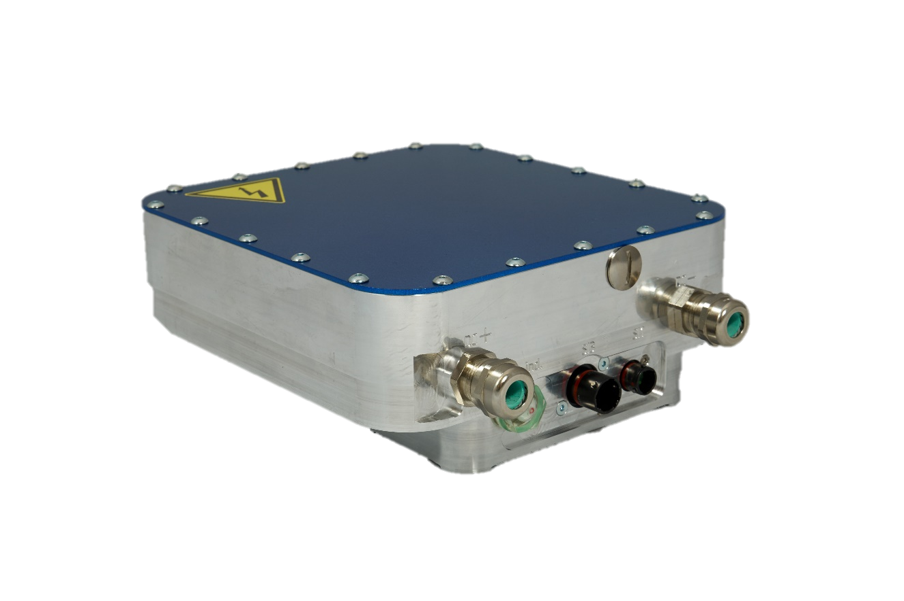

/// Custom Inverter Solutions

At SciMo, we are specialized in creating highly custom inverter solutions. Our streamlined design process allows us to quickly adopt supporting mechanical hardware, ensuring a fast turnaround time for our clients.

If you’re interested in learning more about our custom solutions, please visit our website for more information.

/// News

/// 2023

First eSTOL Aircraft Flight with SciMo SY43.B generator

Electra has successfully completed the first flights of its EL-2 Goldfinch, a hybrid-electric, ultra-short takeoff and landing (eSTOL) aircraft. The aircraft is powered by eight electric motors, enabling ultra-short takeoff and landing. A SciMo SY43.B generator in combination with a SciMo ISI2 inverter is used to enable long ranges without recharging on the ground.

More information at:

https://www.electra.aero/news/worlds-first-hybrid-electric-estol-flight

/// 2022

SciMo presents a new promotion Video:

For test bench applications up to 30,000 rpm, SciMo presents the SY45 series. Continuous power is over 200 kW and more powerful derivatives follow, as well as solutions up to 40,000 rpm.

The motors are also available with an attached inverter for easy integration into your test bench environment. Of course, we are happy to respond to individual requests.

The European Innovation Council (EIC) has awarded SciMo funding of EUR 1.94 million to develop a fully automated winding machine that will enable SciMo’s winding technology, and thus motors with continous power densities of up to 10 kW/kg, to be mass produced. SciMo was awarded the contract as part of the EIC Accelerator funding program, in which 1109 companies applied with their innovative projects in this funding round. SciMo is one of 99 companies that will receive funding to help bring their promising technologies to market. The aim of the eMONIC project is to make the SciMo winding technology suitable for series production and to develop the necessary production automation. This will make it possible to produce SciMo motors, which are currently only available as prototypes or in small series production, much more cheaply and in larger quantities in order to gain a foothold in the e-mobility sector. By increasing material efficiency by up to 75 % and resulting in lighter and smaller motors, SciMo will also make an important contribution to some of the main goals of the European Green Deal such as:

- Accelerating the transition to sustainability and smart mobility.

- Transitioning industry to a clean and/or circular economy

- Increasing the climate change mitigation and/or adaptation targets of the EU

/// 2021

SciMo presenting at the Hannover Messe: „New electric motor technology for challenging applications“ by Dr.-Ing. Markus Schiefer.

Along with our partners from the Cluster Electric Mobility South-West, the Stuttgart Region Economic Development Corporation, Baden-Württemberg International and in cooperation with Ontario (Canada), the State Agency e-mobil BW has put together a two-and-a-half-day expert program on new mobility solutions and automotive themes especially for the digital edition of Hannover Messe.

Thank you for giving us the opportunity to contribute for this program.

/// 2020

We are starting manufacturing the SY43 in small volume production. There are different configurations available. The high speed version has a maximum speed of 30.000 rpm. The weight is slighlty above 13 kg. Dependend of the type of coolant a peak power of 180 kW and continuous power of 100 kW can be achieved. The SY43 is ideally suited to be controlled by our ISI2 inverter.

The SY43 is a universal machine, that can be used in a wide range of applications.

Our customers appreciate us as a reliable and quality focussed partner. Our in-depth know-how for the production of milled parts as well as turned parts enables us to produce special parts for mechanical engineering in a high quality, precise and timely manner. Our CNC machining offers precision as well as standard parts, turned parts, semi-finished parts, gearings, shafts, rotors made of different materials like e.g. carbide, steel, aluminum.

/// 2019

SciMo is proud to announce that we have passed an in-depth set of assessments to achieve the honor of ISO-9001:2015 certification for our quality management system

ISO 9001:2015 is the most widely known and internationally accepted standard for quality management. This certification recognizes organizations with a quality management system that consistently provide services that meet customer and regulatory requirements.”

The ISO-9001:2015 standard ensures that the basis of our quality management system is continuous improvement and customer satisfaction.

We are certfied by the TÜV Hessen.

Middle of October we could finally move into our new office rooms. This gives as more space for our new employes and we can increase the number of test benches for 24/7 testing. We are now working on 280 qm.

/// 2018

Since the beginning of 2018, SciMo occupies a new hall in Karlsruhe Rheinhafen.

Besides the motor prototype construction and the electronic production, we are specially proud of our brand new 3-axis CNC-milling machine and the 5-axis CNC-rotating milling center, both of them from DMG Mori.

For the construction of the fully automated winding technology with the highest filling levels, SciMo´s grant from the State of Baden Württemberg has been extended.

We are very pleased about this extension!

For the TU Delft Hyperloopteam, SciMo cosntructed our very own overworked strong velvet motor. The motor has a power of 200 kW with only 11,5 kg weight. The corresponding converter adds only over 6 kg weight. Unfortunately we must settle for second place.

/// 2017

The Munich WARR-Team wins the SpaceX Hyperloop competition in August 2017 again after winning this competition already in August 2016. The Munich pod, powered by the SciMo could reach a maximum velocity of 201 mph within a 0.8 miles short track. Congratulation to this exceptional success!

After an intense season and a constant head-to-head race with the teams from Delft, Stuttgart and Zurich, the Formula Student team from Karlsruhe was able to make the first place in the world ranking list for the first time in the club history.

The KIT16e electric racing car is powered by four motors that were developed in cooperation with KaRaceIng.

SciMo receives the ‚exist‘ funding from the German Federal Ministry for Economic Affairs and Energy for the foundation of ‚SciMo – Elektrische Hochleistungsantriebe GmbH‘.

/// Quality

Our customers expect and require the highest quality, reliability and functionality of our products. We as SciMo are aware of this responsibility.

Our employees are significantly involved in the implementation of these attributes. With their commitment and innovative strength, they are the driving force of our company.

The basis of our daily activities is a quality management system according to ISO 9001, which has been certified in 2019. Furthermore, cooperations with our customers and partners from the automotive industry support us in the continous improvement of our quality management to ensure highly reliable manufacturing processes for highest quality.

/// Company History

EIC Accelerator

SY43 production

Production Facility expanded

ISO 9001

Production Facility

WARR Hyperloop

WARR Hyperloop

Founding of SciMo

Power Density Record

KaRaceIng

KaRaceIng

/// Founders

‚SciMo – Elektrische Hochleistungsantriebe GmbH‘ was founded on the 6th of June in 2017 by a group of Ph.D. students from the Karlsruhe Institute of Technology.